Custom pipe bends offer better flow characteristics and eliminate countless welds over factory elbows or forged fittings. Plus, pipe bends are a basic necessity if smart pigs are deployed throughout the system.

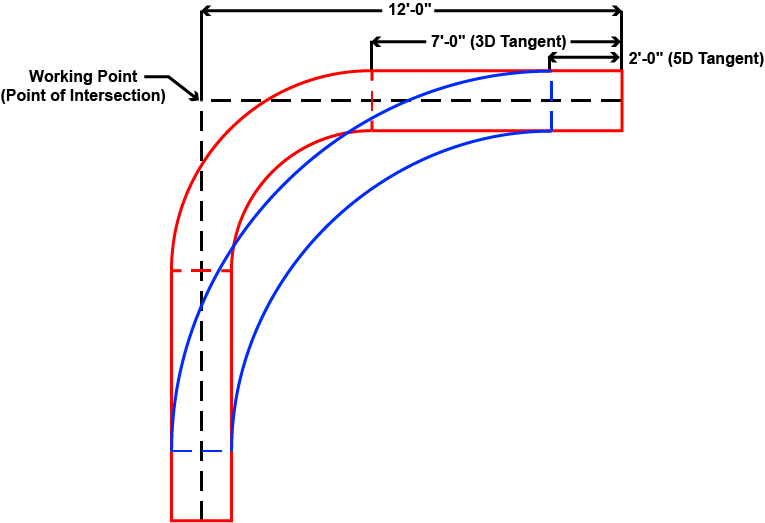

20″ 3D vs. 6D – Material Utilization

| Bend | Angle | Radius | Arc Length | C/E | Tan A | Tan B | O.A.L. | Material Saved |

|---|---|---|---|---|---|---|---|---|

| 3D (red) | 90° | 5′-0″ (3D) | 7′-10 1/4″ | 5′-0″ | 7′-0″ | 7′-0″ | 21′-10 1/4″ | N/A |

| 6D (blue) | 90° | 10′-0″ (3D) | 15′-8 1/2″ | 10′-0″ | 2′-0″ | 2′-0″ | 19′-8 1/2″ | 2′-1 3/4″ |

Benefits Include

Fittings are forged, mass produced products that cannot be custom ordered very easily.

Fittings typically have limited angles and limited radii.

A general misconception is that the cost is lower for a mass produced compared to a custom product; in the case of pipe fittings this is not necessarily true.

Induction Bends

- Custom Angles

- Custom Radius

- Better Piggability

- Coated before bends ship

- No PUP’s needed for install

- Entire bend including tangents can be made from mother pipe

Fittings

- (2) Extra Welds to add PUP

- Extra cost to purchase PUP

- (2) Extra Welds to X-Ray

- Need additional 12′ line pipe to cover same span

- Extra logistics with PUP’s